-

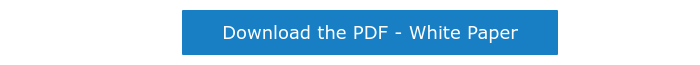

Engineering data and analytics lifecycle

-

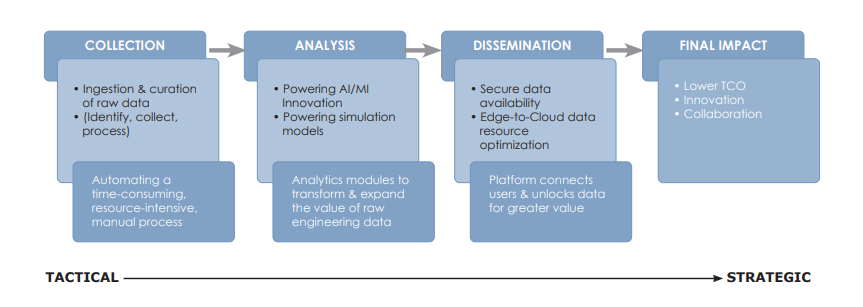

Bring engineering data to light through centralization

-

Operationalize data, ai/ml models and analytics code

-

Cost optimized Data Management

-

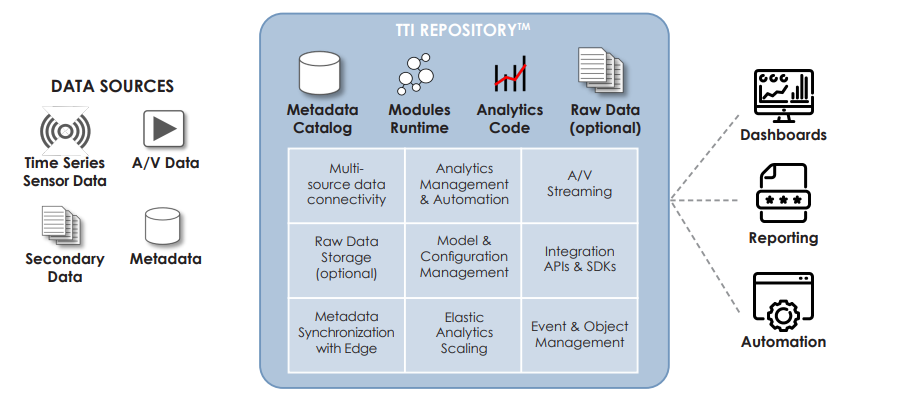

Engineering data and analytics repository

How globally integrated teams can unlock critical engineering data and analysis with an engineering repository

As an engineering leader, you are tasked with shortening product development lifecycles and becoming more agile. You need to optimize the iterative design process and even cut cycle times in half. That’s why you’re committed to the transformation of your organization’s core processes and technology infrastructure, helping to lower costs, improve efficiencies, increase performance, and provide a path to the cloud for your global engineering teams.

However, you also know that engineering poses unique challenges in data and analytics management, which must be solved before digital transformation can deliver greater value to the organization. Traditional IT solutions usually do not conform to engineering-specific needs, workflows, data, models, and analysis tools. Engineers often lack an integrated and automated way to gather, share, and analyze the sensor-based time-series and structured data generated in their daily workflows. Without rethinking the digital transformation of these fundamentals, engineering organizations cannot share data and analytics assets. In addition, efficiencies are limited, resulting in cumbersome, manual processes that will slow product development cycles.

In this white paper, we examine the challenges and opportunities that engineers encounter in their digital transformation journey, especially in optimizing the value of their data, analytics code, and models across global engineering teams. We also share a number of insights gathered from discussions with our customers that underscore the need for solutions designed to manage engineering data, analytics, and AI/ML modeling.

CURRENT CHALLENGES FOR ENGINEERING DATA

Digital transformation for engineering core processes is dramatically reshaping businesses, enabling engineering organizations to accelerate product development and reduce liabilities. Digital transformation in engineering enables a connected “digital thread” that links designs, test data and analysis with the digital representation of products under development. This allows organizations to increase visibility and control over quality, costs, timelines, and profitability. The digital thread is critical to digital engineering, and it places an emphasis on authoritative sources of data, digital modeling techniques, and data analytics.

In effect, engineering analytics and data — the heartbeat and lifeblood of a manufacturer — is often locked at the edge in test labs, rigs, and devices in the field. This data is part of the digital thread, yet organizations cannot fully realize its value.

However, digital transformation is still a work in process for much of the engineering world. Solutions that have worked well for IT in eliminating siloed data and transforming business workflows have not worked equally well in engineering. Data is often large, engineering-specific binary data sets that include time-series channel data (data corresponding to the sensor values) collected at potentially high frequencies and for long periods of time. As such, it is not well-suited to traditional IT database structures and software. It is siloed, difficult to share, difficult to move around, and often not available in a form that can readily add value in other areas of the organization.

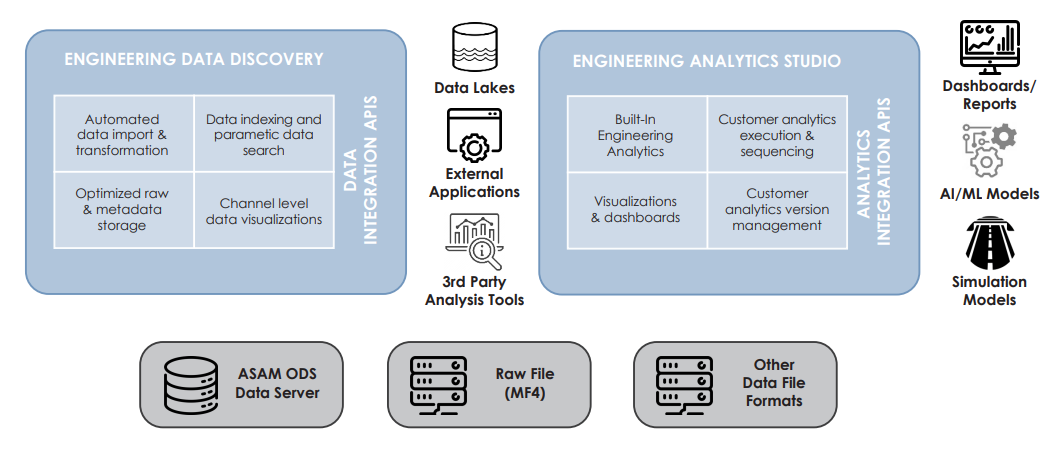

ENGINEERING DATA AND ANALYTICS LIFECYLE

According to recent industry studies, engineers spend roughly 70-80% of their time preparing data for analytics and only 20-30% of their time on analysis and model training (Bridging the Gap Between Engineers and Data Scientists, Forbes, June 30, 2021). While the constantly increasing volume of data demands that analytics move into hyperdrive, systems supporting management of analytics code, data and models have lagged.

Despite the promises of digital transformation, many engineering organizations are still challenged to support:

• data, analytics and models that are available centrally to the entire organization

• fully operationalized and automated data, analytics, and model management processes

• scalable and extensible compute resources that leverage cloud concepts

• total cost of ownership optimized for current and future compute and storage resources.

WHAT OUR CUSTOMERS ARE SAYING

Over the past several years, we have listened carefully to what our customers say about digital transformation and data

engineering. Engineering teams are seeking Based on these conversations, here are several key drivers that suggest the

industrywide need for an engineering data repository solution.

VIVIOTA ENGINEERING DATA AND ANALYTICS VALUE MODEL

BRING ENGINEERING DATA TO LIGHT THROUGH CENTRALIZATION

No one knows better than engineers about data growth at the edge. The Gartner analyst group predicts that 75% of enterprise-generated data will be “created and processed outside a traditional centralized data center or cloud” by 2025, up from 10% in 2018. While the constantly increasing volume of data at the edge demands that analytics be forced into hyperdrive, at Viviota we found that until global engineering organizations can centralize their data and analytics for collaboration, they remain mired in unscalable, inextensible workflows and processes. Unless we improve this, the Digital Thread will remain an unattainable pipedream.

Engineering also has first-hand experience with the fact that the more voluminous, diverse and complex data becomes,

the more difficult it is to manage. Cleaning, filtering, curating, and enriching data using analytics, and cataloging data is

time consuming. Adding to this complexity, in many companies, engineering operations are not centralized and include

hundreds of data nodes residing in R&D labs, simulation labs, physical testing facilities, and in-service sites.

They need a common way to govern data, support modelling, and manage analytics to locate, track and retrieve

and gain the highest value from data and core engineering IP. This requires a system that is defined and managed by

engineering, but not built by engineering. The system must be flexible enough to accommodate all types of engineering

data, and agile enough to be practical.

OPERATIONALIZE DATA, AI/ML MODELS AND ANALYTICS CODE

Traditional business intelligence and data warehousing systems usually do not work with engineering data. What’s more, simply transforming data pipelines and workflows and centralizing access to drive new and faster levels of collaboration across engineering stakeholders is not enough and does not provide the scalability they need.

To properly support their digital transformation initiatives, engineers need to operationalize their data, analytics and AI/ML models. This involves standardizing the ways they gather, manage and share their data, using well-established methodologies employed for other corporate data, along with processes that work specifically for engineering.

More specifically, engineers need an advanced yet easy-to-use engineering infrastructure to manage data, models and analytics created in the process of product development. Versioning code, models and data in a central repository allows for an ongoing record of changes over time and workflow automation allows for rapid validation of models, code and even captured data as new versions are released.

With data management processes standardized and operationalized, organizations can enhance their engineering capabilities, including true collaboration across engineering teams within a global computing environment.

PROVIDE ENGINEERING WITH ITS OWN FLAVOR OF THE CLOUD

In working with our customers, we found the traditional engineering tool sets did not include cloud-based solutions. Their engineering workflows had not relied on IT for solutions and tool sets were adopted to solve the technology needs for the job at hand, so engineering had been cut off from the full benefits of the cloud. Engineers are also not IT professionals and working a cloud strategy into engineering had not been one of their priorities. However, engineers are looking to the cloud as a means to leverage scalable, cost effective compute and data storage accessible to the globally integrated organization.

We believe that engineers should not be required to become cloud experts. Engineering needs its own flavor of the cloud that offers ease of management, scalable resources for computing and storage resources, and efficient, consumption-based usage models. Engineers need a package they can easily access and deploy at an on-prem datacenter, on the cloud, or on a hybrid platform of the two. This model can offer on-demand availability of system resources, especially data storage and computing, without direct management by the user. The model can also be optimized for use at multiple locations.

Engineering needs to be able to build their infrastructure separately from IT, but in such a way as to leverage existing IT infrastructure such as the cloud, to take advantage of those resources when appropriate. Engineering also need tools that will comply with IT policies and safeguards but are accessible and usable by engineering personnel.

DEVELOP AN EFFICIENT, AUTOMATED WAY TO OPTIMIZE SPEND FOR CLOUD-BASED COMPUTING RESOURCES

Once our engineering customers have access to new tools and resources for digital transformation, they need to optimize their engineering costs, including expenses for cloud resources. More specifically, they need a way to automatically select and assign the right resources to a workload or application to optimize spend on storage by leaving some data at the edge and allowing it to be indexed across a cloud instance and leveraging elastic compute capabilities in the cloud to dynamically spin up and down analysis and data processing nodes in support of AI/ML, Deep Learning and other Digital Engineering initiatives.

Traditionally, baseline performance is managed by applying domain knowledge to the manual selection of cloud resources for a workload. With automation, workload performance, compliance, and cost can be accurately and continually balanced against the best-fit infrastructure in real time. Cost-efficiency can be further optimized by the use of ML, cultivating data and improving efficiency for more value over time.

VIVIOTA TTI REPOSITORY: AN ENGINEERING DATA AND ANALYTICS REPOSITORY SOLUTION FOR GLOBAL ENGINEERING

In response to the needs of today’s engineering organizations, Viviota offers TTI Repository, the first engineering repository for global teams operationalizing and sharing complex engineering data and analytics such as AI/ML models. viviota.com/tti-repository/

Purpose-built for engineers, TTI Repository is designed to help:

• automate management of the digital thread

• operationalize data, models and analytics code

• centralize resources supporting global collaboration

• provide a pathway to cloud-based computing environments

• give engineering management insights and better control over the product lifecycle

• optimize the use of current and available compute and storage resources

• provide deployment flexibility, scalability and extensibility for data, analytics, and model management

• support secure systems that mitigate the risk of tampering and loss

VIVIOTA TIME-TO-INSIGHT REPOSITORY™

TTI Repository provides a platform connecting global engineering teams to their data and analytics assets, wherever they may be. For example, an engineering team member in Stuttgart can access the data being generated in Japan, and analytics from Detroit — all through one interface. The platform can be deployed in an on-prem data center, cloud environment or a hybrid of the two. TTI Repository works in concert with Viviota TTI Analytics Studio™ or other software connecting edge data resources.

With TTI Repository, engineers can leverage the power of AI/ML, simulation and other advanced analysis capabilities,

helping to support the digital transformation of their organization.

VIVIOTA TIME-TO-INSIGHT

ABOUT VIVIOTA, INC.

Viviota software fills a critical gap in the Digital Transformation initiatives of manufacturing Engineering and R&D teams tasked with product development. Viviota provides engineering organizations software to manage engineering and scientific data, automate time-consuming workflows and enable advanced analytics, maximizing the value of engineering data whatever its source—simulation, testing, production or operational—while minimizing the time and cost

for engineering tasks and shortening product development cycles. Viviota is an NI Alliance Partner, Hewlett Packard Enterprise Business Partner and member of the HPE Edgeline Innovation Network. Viviota is based in Austin, TX. www.viviota.com